LAB1 is a 300m3 climatic chamber inside of which three cold rooms are installed, used as calorimeters to test the efficiency of refrigeration monoblocks. It is possible to carry out performance, energy consumption and efficiency measurements according to EN 17432 for air or water-cooled systems. LAB1 has been designed to check the cooling capacity with ambient temperatures ranging from -10°C to +55°C and with cold room temperatures down to -40°C. In LAB1 is possible to test chiller.

LAB2 is a large calorimeter with a double cold room equipped with a cavity to eliminate heat loss towards the external environment. It was designed to test the performance and efficiency of forced convection air-cooled evaporators for refrigeration according to EN 328 and allows you to measure cooling capacities from 200 W up to 65 kW, with extremely high accuracy and repeatability of the data across the entire measurement range. It is also possible to test the fluid dynamic efficiency of thermostatic valves and fluid control systems. If necessary, LAB2 can be transformed into a climatic chamber for tests on refrigeration systems by simulating external temperatures down to -30°C. This chamber, together with LAB3, is designed also for compressors test according to Annex AA - UL - EN 60335-2-34.

LAB3 is a 300m3 climatic chamber equipped with 8 calorimeters to measure the performance and efficiency of compressors (EN 13771-1; EN 12900) and condensing units for refrigeration (EN 13771-2; EN 13215) and therefore, verify the necessary data for the declaration of conformity to the ECODESIGN regulation. The refrigeration and air handling units of LAB3 allow climatic environments to be created between -15°C and 55°C. Condensing units can be tested with a cooling capacity range between 300 W and 100 kW. In LAB3 it is also possible to perform tests on air conditioners, liquid chillers, heat pumps for ambient heating and cooling and chillers for process cycles. These tests are carried out according to the standards EN 14511 and EN 14825 for partial load evaluation and to calculate the seasonal performance.

LAB3 has been designed and built to safely perform tests on CO2 or Hydrocarbon systems (R290, R600, etc.). Therefore, it has evacuation and environmental remediation systems controlled by very high resolution sensors which allow any risk to be instantly eliminated in the event of very minor leaks of CO2 or hydrocarbons.

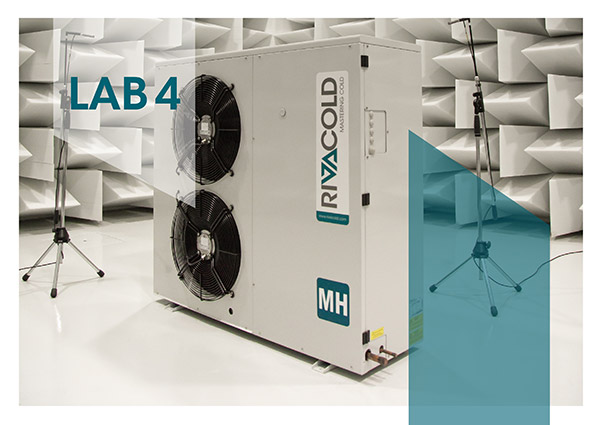

LAB4 is a semi-anechoic chamber, specifically designed and built to perform noise and vibration tests on any product, with particular attention to the acoustic and vibrometric analysis of refrigeration systems. The system allows condensing units to be connected to external acoustically decoupled calorimeters to reproduce any cooling load in any operating condition. The semi-anechoic chamber is also air-conditioned. This way it is possible to reproduce any cooling load and external environment condition, thereby allowing even extreme operating conditions to be simulated. Acoustic and vibrometric data can be acquired and measured simultaneously with machine performance and operating data (temperatures, pressures, etc.) to associate every acoustic phenomenon with a specific operating condition.

LAB4 allows tests to be performed according to EN ISO 3744, EN ISO 3745, EN 13487, EN 12102 series, EN IEC 60704-1/60704-3/60704-2-14.

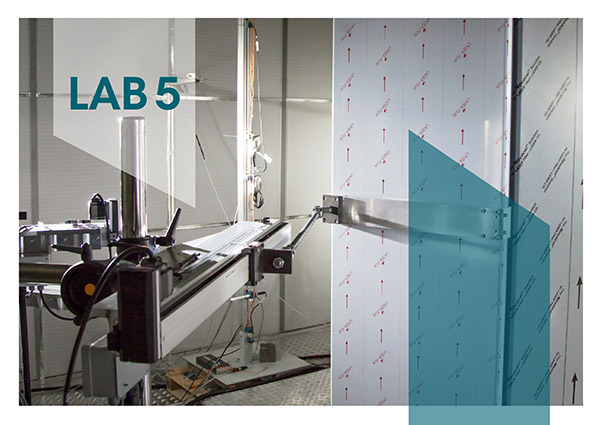

LAB5 is a climatic chamber built specifically for necessary energy efficiency tests for verifying compliance with the ECODESIGN regulation and the declaration of energy class relating to domestic and professional refrigeration systems and for display and sales. The chamber is equipped with a horizontal laminar flow ventilation system that guarantees an air speed between 0.1 and 0.2 m/s at every point and temperature and stability control that guarantees chamber stability of +/- 0.2°C and +/- 0.3% relative humidity.

In particular, tests can be performed in compliance with the following standards:

In LAB6, we can test the corrosion resistance of metals or plastic components with an accelerated salt spray test.

If needed, after performing the test, we can perform metallographic microscope analyses on the treated material at dedicated workstations.

LAB7 is a room, or rather an actual bunker, for testing pressurised circuits, with values of up to 500 bar.

The pressure test is performed until the component breaks. Alternatively, a number of pressure loading and unloading cycles can be set, up to a maximum of 500,000 cycles.

In LAB8 we test everything that has to do with CO2, a natural refrigerant, which requires special tools and care.

We conduct performance tests to measure yields and the consumption of condensing units, split systems, multi-compressor packs, gas coolers and evaporators, using a calorimeter, mass flow meters and enthalpy jump.

| Refrigerated storage cabinets and counters for professional use | |

|---|---|

| EN 16825:2016/A1:2019 + Reg (EU) 1095/2015 05/05/2015 EU OJ L177 08/07/2015 + REG (EU) 1094/2015 05/05/2015 EU OJ L177 08/07/2015 | Tests in accordance with the reference regulation and Declaration of conformity with the European regulation relating to ECODESIGN and the European regulation relating to ENERGY CLASSIFICATION |

| EN ISO 22041:2019/A1:2019 + REG (EU) 1095/2015 05/05/2015 Eu OJ L177 08/07/2015 + REG (EU) 1094/2015 05/05/2015 EU OJ L177 08/07/2015 | Tests in accordance with the reference regulation and Declaration of conformity with the European regulation relating to ECODESIGN and the European regulation relating to ENERGY CLASSIFICATION |

| Refrigerated cabinets to display and sell | |

| EN ISO 23953-2:2015 EN ISO 23953-2:2023 |

Tests on Plug-in units and on systems with remote units Energy consumption, Defrosting, Water vapour condensing and Linear dimensions, volume and area tests, temperature test and Leak test |

| Commercial beverage coolers | |

| EN 16902:2016 | Tests on units with integrated refrigeration system integrated Electricity consumption test, temperature test. Leak test for doors and roofs. Condensation of water vapor. |

| EN ISO 22044:2022, ISO 22044:2021 | Tests on units with integrated refrigeration system integrated Electricity consumption test, temperature test. Leak test for doors and roofs. Condensation of water vapor. |

| Frozen counters | |

| EN ISO 22043:2020, UNI EN ISO 22043:2021 | Tests of electrical energy consumption, temperature, water vapour condensation, dimensions, durability for the lids, on closed horizontal deep-frozen benches for prepacked ice cream with access from above through transparent or opaque covers |

| Household refrigerators and wine cellars | |

| EN 62552-1:2020/A11:2024, IEC 62552-1:2015/A1:2020 + EN 2552-2:2020/A11:2024, IEC 62552-2:2015/A1:2020 + EN 62552-3:2020/A11:2024, IEC 62552-3:2015/AMD1:2020 | Energy consumption, volume, storage, cooling capacity, freezing capacity, ice production capacity on domestic refrigerators and wine cellars |

| EN 60704-14:2013/A11:2015/A1:2019/A 2:2024 + EN IEC 60704-1:2021 + EN ISO 3744:2010, IEC 60704-2-4:2013/AMD1:2019 + IEC 60704-1:2021 + ISO 3744:2010 | Air noise determination test |

| Compressors for refrigerants | |

| EN 13771-1:2016 | Performance test of refrigerants compressors |

| Refrigeration condensing unit | |

| EN 13771-2:2017 + EN 13215:2016/A1:2020 + Reg UE 1095/2015 05/05/2015 GU UE L177 08/07/2015 | Performance tests and Declaration of conformity with the European regulation relating to ECODESIGN |

| Heat pumps, Liquid chilling packages, Process chillers | |

| EN 14511-2:2022 + EN 14511-3:2022 + EN 14511-4:2022 EN 14825:2022 |

Air Conditioners, Liquid refrigerators and Heat Pumps with Electrical Compressor for Ambient Heating and Cooling, and Process Cycle refrigerators with Electrical Compressor |

| Heat exchanger - Forced convection air coolers for refrigeration | |

| EN 328:2014 | Portata d’aria nominale/Nominal air flow rate, rated fan power (0.2 kW - 30 kW) |

| Noise sources | |

| EN ISO 3744:2010 | Sound power levels and sound energy levels of noise sources by measuring sound pressure |

Meaning of accreditation

The accreditation guarantees the competence, the independence and the neutrality of the certification, inspection and test bodies as well as of the test laboratory. Moreover, it guarantees the suitability to value the legality of goods and services according to the voluntory and to the compulsory rules.

Accredia is the competent body designated by the italian Government to certify the competence, the independence and the neutrality of the bodies and the laboratories.

Being an impartial authority, Accredia, guarantees the reliability of the work done by the bodies and in the laboratories carrying out a service in the public interest.

The accreditation ensures that the certification, inspection and test bodies as well as the test laboratories meet all the requirements for the standards. Worldwide, the accreditation is carried out according to the international standard ISO/IEC 17011. In the European Union, the European regulation 765/2008 states that each Member State nominates the competent national authority and conferred to this activity for the first time a legal status, considering it as a public authority.

In Italy, the only competent body designated by the Government is Accredia.